Our diversity in plastics

In a single plastics industry we have different possibilities for refrigeration and cooling. Did you know? As an example, let’s talk about our customers at Raimundo Juliano Indústria de Bebidas Ltd.

They found us through industry partners and application consultants for industrial projects. In this process we provided a smaller equipment with approximately 30,000 kcal/h for blow mold cooling and 170,000 kcal/h for cooling the heat exchanger in a combination of solution x potable water. To complement this system, we also put in a cooling skid for cooling drinking water as well.

In addition to improving the quality of drinking water, with less carbonation and smaller bottle thickness, the REFRISAT equipment used in this process managed to increase the production of bottles made on the blower, and all this with better quality in the part.

Have you ever thought of modifying an entire plastics and beverage production line with only good and technological refrigeration products? That’s why we are everywhere.

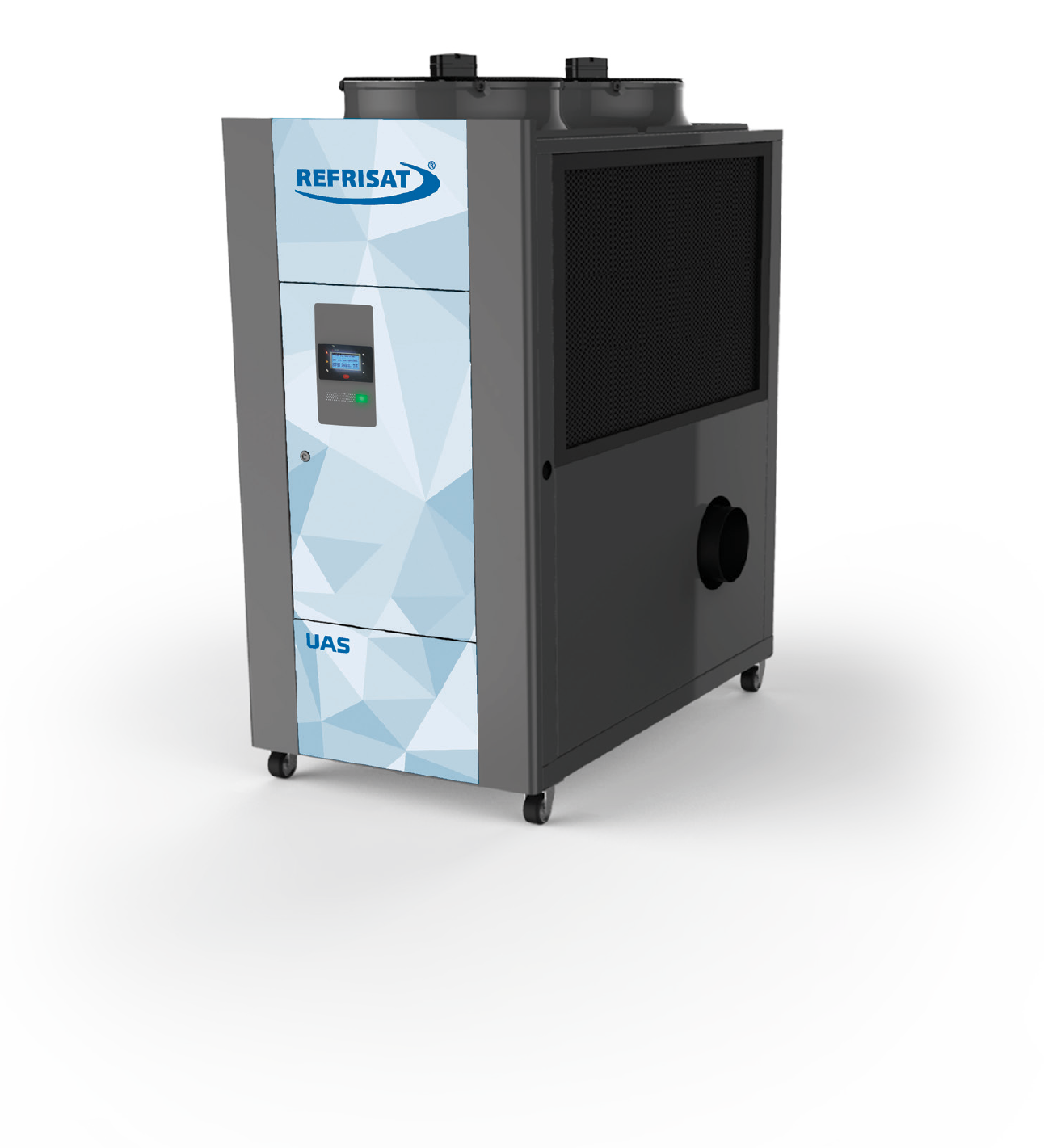

Check out a photo of this process with one of the equipment and the cooling skid:

|  |  |

| Compact Coolers | Dry Air Unit | Drycooler |