Chiller milk cooling: the alternative to dangerous ammonia.

The food sector, in addition to being essential, is extremely sensitive to health needs. And that is why today we chose the Dairy Cooperative of Vale do Paraíba as one of the themes of our News for this two-month period.

In a mix of responsibility and inspection, which was previously cooled in archaic processes with toxic and dangerous chemicals, today it can be done in a more reliable, clean and practical way. So why not change the old milk cooling structure in dairy companies? From dangerous ammonia cooling to refrigeration equipment like REFRISAT.

WHAT HAPPENS TODAY?

We know of many companies in the milk sector that still maintain a dangerous and archaic structure for refrigerating milk with ammonia, mainly because they want to maintain old structures with the idea of economy and low cost.

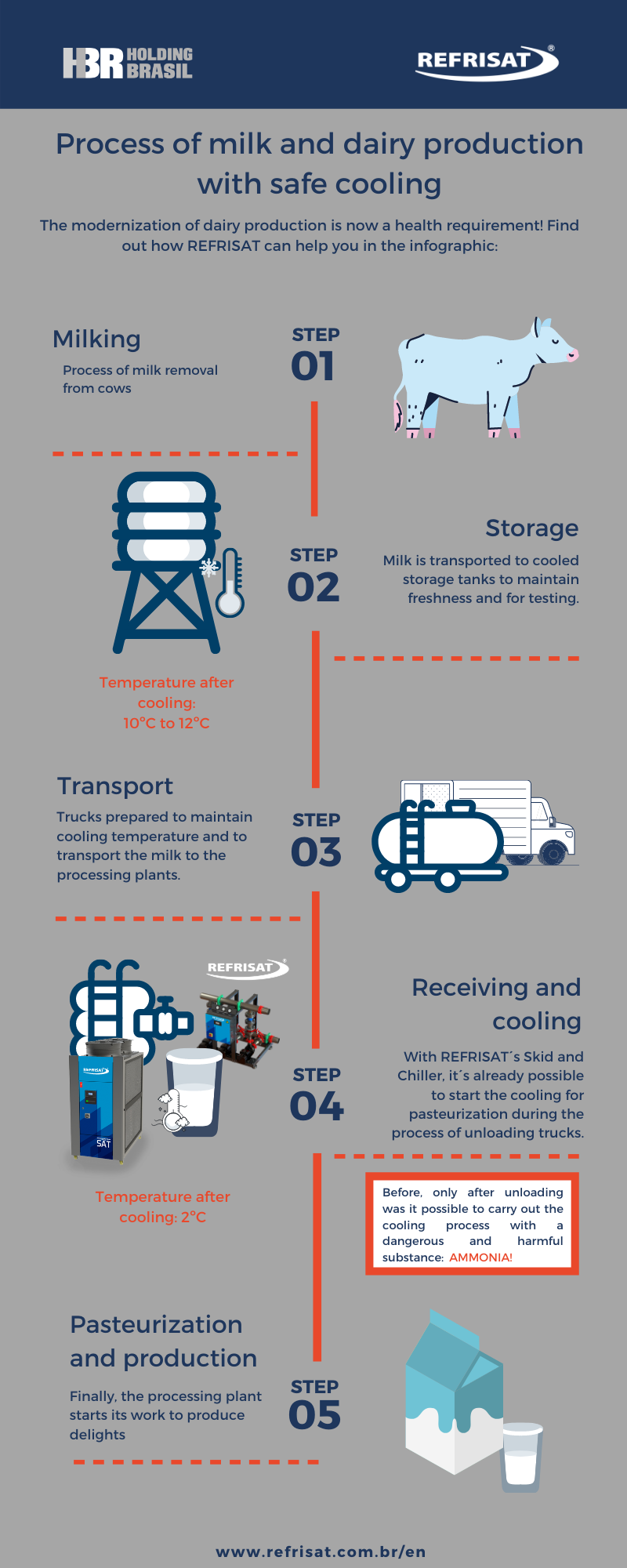

In these companies the process is almost always the same:

1-Cool raw milk in a common cooler, reaching a temperature of 10ºC to 12ºC;

2-Send at this temperature to a pick-up truck that delivers to dairy companies to manufacture derivatives;

3-Upon receipt of this milk, even to ensure the elimination of bacteria and fungi before processing, there is a cooling of the milk to 2ºC by a process that uses ammonia.

** Check out the infographic at the end of this article!

Why is this process problematic?

Ammonia may have been a viable alternative when we did not yet have affordable and developed technology for this sector. Nowadays it is first of all a dangerous chemical, corrosive and can, above all, infect the final product to the point of having a noticeable characteristic smell and causing health problems.

In some companies the leakage of this substance required medical attention from their employees, in addition to double care with PPE and handling the substance.

How to ensure cooling without ammonia?

Like our work with our Comevap customers, REFRISAT is able to replicate the solution we developed for them in replacement of ammonia cooling for the entire market.

In the case of Comevap, we provide equipment with high capacity and control features, coupled with a refrigeration skid that has a sanitary heat exchanger. In this Skid, the circulation of liquid is made possible immediately after unloading the delivery trucks. Therefore, in addition to ensuring sanitary rules, without polluting or leaving impurities in the milk, the process guarantees cooling from 10ºC – 12ºC to 2ºC or according to the sterilization / pasteurization / treatment rules of the dairy company receiving this product.

Our chiller works in conjunction with the skid ensuring the cooling of the milk when leaving the delivery trucks.

More milk, more life, more responsibility and better products after all.

|

|

|

COMPLETE PORTFOLIO |

MEDICAL HOSPITAL AREA |

DATACENTER |